Temperature Recorder as a Kashrus Tool

Rabbi Dovid Cohen

Administrative Rabbinical Coordinator of the cRc

February 2008

There are many times when technology helps us improve our kashrus supervision, and the following are three examples where relatively inexpensive temperature recorders have been used for exactly that purpose. To the best of our knowledge, Rabbi Elisha Rubin (OK) originated the idea to use the first suggestion given below,1 and Rabbi Yaakov Blugrond z”l (OU) is the innovator of the last one.

Aino Ben Yomo

Every Monday morning a specific company kashers a few kettles before starting its kosher production for the week and claims that it never has a production run on Shabbos and Sunday. The Mashgiach for this company is not 100% convinced that this claim is always true and wants to be sure that the equipment is in fact aino ben yomo when he comes to kasher. We have found the LogTag Trix-8 data logger to be an inexpensive solution to this question.2

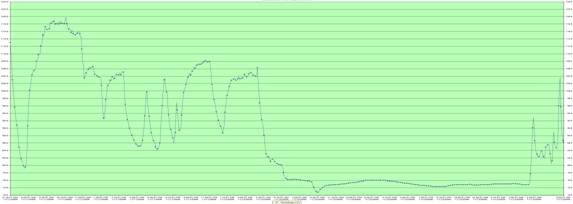

The recording device is about the size of a credit card and just about ½ an inch thick. The data logger has a hole in one corner and can be attached to the equipment that will be monitored either with a wire seal going through the hole, or with tape as in the picture at right. When the Mashgiach comes to the plant, he can easily connect the data-logger to his laptop and instantly see a chart of the last 8,000 data recordings,3 as shown below. The drop in temperature is quite clear, and on the computer screen the Mashgiach can read the numbers even more clearly. In this case, the chart shows that the equipment was is in fact aino ben yomo as it was not used from about 3:00 A.M. on the 12th until about 5:00 A.M. on the 13th, when the kashering began.

The recording device is about the size of a credit card and just about ½ an inch thick. The data logger has a hole in one corner and can be attached to the equipment that will be monitored either with a wire seal going through the hole, or with tape as in the picture at right. When the Mashgiach comes to the plant, he can easily connect the data-logger to his laptop and instantly see a chart of the last 8,000 data recordings,3 as shown below. The drop in temperature is quite clear, and on the computer screen the Mashgiach can read the numbers even more clearly. In this case, the chart shows that the equipment was is in fact aino ben yomo as it was not used from about 3:00 A.M. on the 12th until about 5:00 A.M. on the 13th, when the kashering began.

Dedicated Equipment

Another company uses a mixer for both kosher and non-kosher, with a thorough cleaning between products, and would now like to begin using heat to slowly dry a hot kosher product on that same equipment. The Mashgiach will check paperwork and make unannounced visits to make sure that the equipment is never used for hot non-kosher products, but he would like extra assurance that no hot productions happen without his knowledge.

To give the Mashgiach the desired comfort level, this company installed a wall-mounted Omega recorder (see picture), which continuously records the temperature on the steam-inlet pipe. The data (a) can be viewed on the display panel, (b) can be downloaded to any computer in the plant and emailed to the Mashgiach as an Excel file, and (c) is stored on a removable memory card which can be connected to the Mashgiach’s laptop.

Drain Condensate

When steam heats a kettle filled with non-kosher product, the condensate formed is considered non-kosher. If that condensate is returned to the plant boiler, it will be reused to heat other products which will compromise their kosher status. One way to avoid this problem is for the company to not recover condensate whenever they use the kettle for a non-kosher product. The question is how the Mashgiach can verify that this was done?

The answer is brilliantly simple. When condensate drains out of the kettle it is boiling hot, so a temperature recorder can be placed on the drain pipe to record whether the required draining actually happened. In other words, if the company cooked non-kosher food from 8:00 A.M. to 2:00 P.M., the temperature recorder should show >200° F condensate passing through the pipe for the entire time; if it does, that would confirm that the company is following the kosher protocol and the other products in the plant remain kosher.

Footnotes

1 See Daf HaKashrus Volume XII Issue #1.

2 For more information on this data logger, go to http://www.microdaq.com/logtag/trix-8.php. Undoubtedly, there are other companies that make similar products, which may be better suited to a particular need.

3 The Mashgiach can program how often the data should be recorded depending on whether he needs many weeks of records or more specific information. In the former case, he might set his recordings 10 minutes apart so that he would get about 8 weeks of data, and in the latter case he might set his recording to be every 30 seconds which would give him about 2.5 days of very detailed data.